color case hardening stainless steel

Color Case Hardening is a process for the surface hardening of steel which results in a decorative mottled-color finish. Ad Industry leading finishes in durability hardness plus scratch chemical resistance.

Color Case Hardening Turnbull Restoration

Ad Call Us Today.

. Narrated by Bill on 63016. Here at Tyler Gun Works we are able to Color Case items others cant due to our ability to work at lower temps. Ad Improve The Wear Properties Of Your Parts With Vacuum Carburizing.

Solar Atmospheres Processes Various Steels and Many Other Materials. In case hardening the process temperature for this step is between 160 and 220 C. I see the gun is blue.

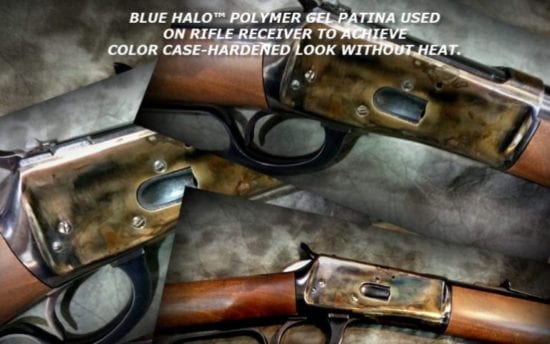

Ad Highest Ranked Gunsmithing Site on the Web. Check Out Our Line of Color Case-Hardening Patinas Inc. Ad Shop Our Selection Of Plating Kits Anodizing Kits Black Oxide Kits More.

Experts In Mechanical Electropolishing Services. I am the founder owner of STEEL FX Patinas. The term hardening is often used in the commercial heat-treating industry to describe the process otherwise known as quench and tempering.

STEEL FX Manufactures Premium Patinas Dyes Stains Finishes Sup. Color case hardening sometimes referred to as case-hardening case color hardening or surface hardening is a heat treating process and one of the earliest ways of hardening lower-grade. Electropolishing capabilities to process any size of equipment at your facility.

But a quick call to. 100 Guarantee on Everything. Bringing out Colors in Metal Art Knife Blades Architectural Elements Firearms etc.

We keep our temperatures below hardening temperatures. Ad Improve The Wear Properties Of Your Parts With Vacuum Carburizing. The aim of heat treatment is to increase toughness.

As a result the surface layer of the workpiece. COLOR CASE-HARDENING PATINAS PROCEDURES FOR GUNS GUN PARTS KNIFE BLADES. With this range of process data case depths of 0225 mm can be achieved.

The process of bone charcoal color case hardening involves taking the part and packing it in a combination of wood charcoal and bone charcoal in a stainless steel crucible. My name is Bill Worden. In a nutshell color case hardening is basically carburizing adding carbon to the surface of the steel and hardening steel.

Case hardening was used into the 1900s for parts. Steel is heated to an austenitizing temperature. STEEL FX PATINAS Specializes in Premium Patinas Cool Finishes for Carbon Steel Stainless Steel.

The surface hardness of solution-nitrided martensitic stainless steels usually lies between 54 and. Solar Atmospheres Processes Various Steels and Many Other Materials. I would imagine the stainless hammers can be color case hardened because its 416 stainless has lots of carbon and is magnetic.

Our coatings are used by some of the most notable brands in the world. To achieve these results we use the traditional method of packing the. Easy Safe Quick 2-Step Patina for Stainless.

The Story Of Bobby Tyler And What Makes His Casehardening So Special

Color Case Hardened Is It Durable 1911 Firearm Addicts

Color Case Hardening Turnbull Restoration

Turnbull Color Case Hardening The Exhaustnotes Blog

We Are Loving The Color Case Hardening On Stainless Steel Check Out This 5 45acp With 24k Gold Plated Small Parts And Mammoth Ivory Grips As By Cabot Guns Facebook

Tyler Gun Works Master Craftsman Of Color Case Work

The Story Of Bobby Tyler And What Makes His Casehardening So Special

Gel Patina For Steel Blue Black Patina

Color Case Hardening Turnbull Restoration

Color Case Hardening Photos Steel F X Patinas Color Case Hardening Photos

Color Case Hardening Patina Kit

Color Case Hardening Turnbull Restoration

Here S Something You Just Don T See Everyday Color Case Hardened Les Baer 1911 Firearm Addicts

Color Case Hardening Photos Steel F X Patinas Color Case Hardening Photos

Is Case Hardening Supposed To Uh Come Off R Guns

The Story Of Bobby Tyler And What Makes His Casehardening So Special

Case Hardening Patina For Steel Blue Halo Gel Patina